|

Specifications for

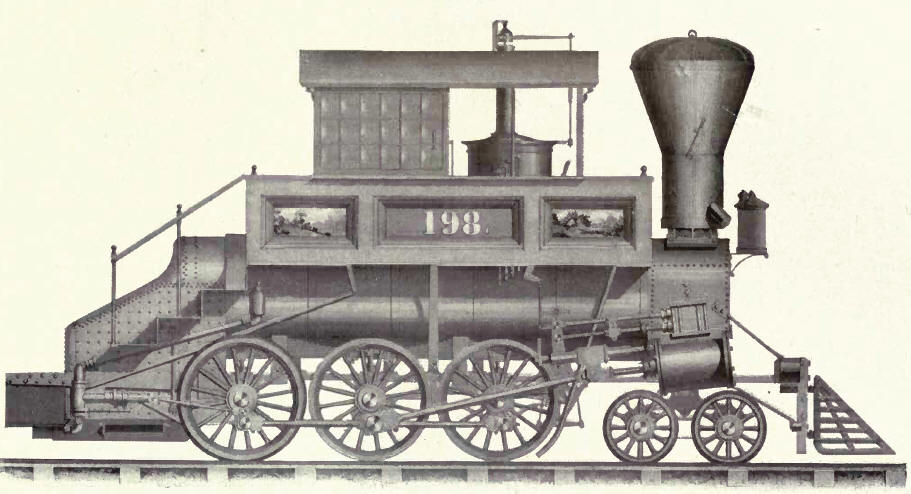

the Baltimore & Ohio RR Locomotives 199 & 204 |

| |

| Confederate Names: #199 -- Dixie; #204 -- Unknown |

| |

| Information found in Bell, The Early Motive Power of the

Mobile & Ohio Railroad, 1912, pages 88-92, reformatted for

ease of reading. |

| |

| #199 was built in November, 1853, and #204 in March, 1854,

both by A. W. Denmead & Sons. |

| |

| Cylinders: 19" x 20" |

| Driving Wheels: 50" |

| Truck Wheels: 28" |

| Weight: 60,000 pounds |

| Boiler shell: 5/16" iron, in straight form |

| Boiler diameter: 48" |

| Number of tubes: 160 |

| Diameter of tubes: 2 1/2" |

| Length of tubes: 14 feet 4" |

| Firebox: 42" x 58" |

| |

| Scroll down for a complete, detailed

description. |

| |

|

|

| |

| The following article appeared in an article by

M. N. Forney, in the American Engineer and Railroad Journal,

was prepared by W. S. G. Baker, and on account of its

completeness and accuracy, is thought to be of sufficient

interest to be hear repeated: |

| The cylinders were 19 x 20 inches, with spring

packing and brass rings on the pistons, the piston rods being of

iron, 2 3/4 inches diameter. The steam ports were 1 1/2 by 14

inches, the exhaust port 2 1/2 by 14 inches, the travel of the

valve 4 1/2 inches. The crossheads were made of brass, with

gun-metal gibs at the top and bottom, arranged with bolt and

wedge-shaped tops to take up wear. The guide rods were of

wrought iron, and of diamond section. The main rods led to the

centre driving-wheels and were 7 feet 7 inches from centre to

centre. The tires for the main and leading drivers were 6 1/2

inches wide and blind, the rear drivers having flanges. The

centres of all the drivers were of cast iron, fitted with

chilled-faced cast-iron tires, put on with a taper fit and held

by lateral hook keys and nuts. |

| The driving-wheels were 50 inches diameter and

52 inches centre to centre. The truck-wheels were 28 inches in

diameter, with chilled faced, placed 36 inches, centre to

centre, and the centre of the truck was 15 feet 8 inches from

the centre of the rear driving-wheels. The main axle was 5 1/2

inches in diameter, the others being 5 inches. The total weight

of the engine was 60,000 pounds, about 48,000 pounds being on

the drivers. |

| The truck bolster was of wrought iron, with its

centre forged on, the journals formed at the ends and fitted

into housings resting upon and keyed to semi-elliptic springs,

36 inches long, the ends of which rested and slid within seats

formed on top of the truck frames. The frames were of wrought

iron, with the pedestal jaws forged on. The jaws were slotted to

shape and fitted with cast-iron shoes and wedges adjustable from

below. The axle boxes were of gun metal and the springs were

semi-elliptic, graduated. They were equalized upon the main

boxes and were connected to the boxes by pins passing through

the frames upon which the springs rested. The frames were

rigidly secured to the smoke-box but were free at the firebox

end and so arranged that the boiler was free to slide upon them

and was held in place by sleeves passing around the frames and

bolted to the firebox. |

| The boiler was horizontal and straight. It was

48 inches in diameter, with single rivetted seams, and was made

of 5/16-inch iron. The dome was 30 inches diameter and 36 inches

high, with a cast-iron flange and top made with a ground joint.

The safety valves were formed in the top and connected by a

lever to a spring balance. The dome was placed 54 inches back of

the front flue sheet. The firebox was of copper, with 5/16-inch

sides and 5/8-inch flue sheet. It was 42 by 58 inches in size

and there were 160 2 1/4-inch flues of lap-welded iron 14 feet 4

inches long. |

| The feed-water was supplied by two

single-action pumps attached to the sides of the firebox and

operated by cranks attached to the crank pins of the rear

driving-wheels. The feed-water entered the boiler by checks

immediately in front of the back flue sheet, and was then

conveyed by a pipe inside the boiler and discharged immediately

back of the front flue sheet. Rocking grates were used, operated

by a lever on the foot-board, with a drop-grate in front. The

drawbar was attached to the ashpan as in the Winans camel

engines. |

| The valve gear was of the hook type, with

cut-off worked at half stroke, and operated by a separate

eccentric and rocker. The vale stem of the cut-off was so

arranged that it could be thrown out of gear, the valve

remaining stationary when the cut-off was not used. |

| Steam was taken from the top of the dome

through a slide-valve throttle, operated by a crank connected to

a screw with large pitch. The gage cocks were in the waist of

the boiler below the foot-board of the cab and operated by long

stems and levers. The pilot in front of the engine was so

arranged that it could be folded back when not on the road. This

was done to permit of closing the doors of the engine house when

the engine was in the stall. The smoke stack was arranged for

soft coal fuel. It was formed with a centre pipe 12 inches in

diameter, over which a cast-iron deflector was placed. This was

to deflect sparks into a hopper formed by a second pipe, with a

space between it and the central one. This space was provided

with an outlet at the bottom to facilitate the removal of

accumulated sparks. The top was provided with a bonnet hinged to

the stack and covered with iron netting. |

|